Last SLA printer I touched was the original Anycubic Photon with Anycubic cure & wash with Anycubic tough resin. Looking at all the current options I am lost what I should buy. Resin heating, pressure detection, vat tilting and all of this wasn't a thing back than.

With the past experience in mind what printer, curing staton & resin should I get?

for the printer:

First three points have to be fullfiled. The others aspects are more nice to have.

- relaible!!! I want to start a print and return once it is done. Not worrying about print failures

- Works with a good slicer. Back in the day I used PrusaSlicer with UV-tools to convert it to Anycubic fileformat.

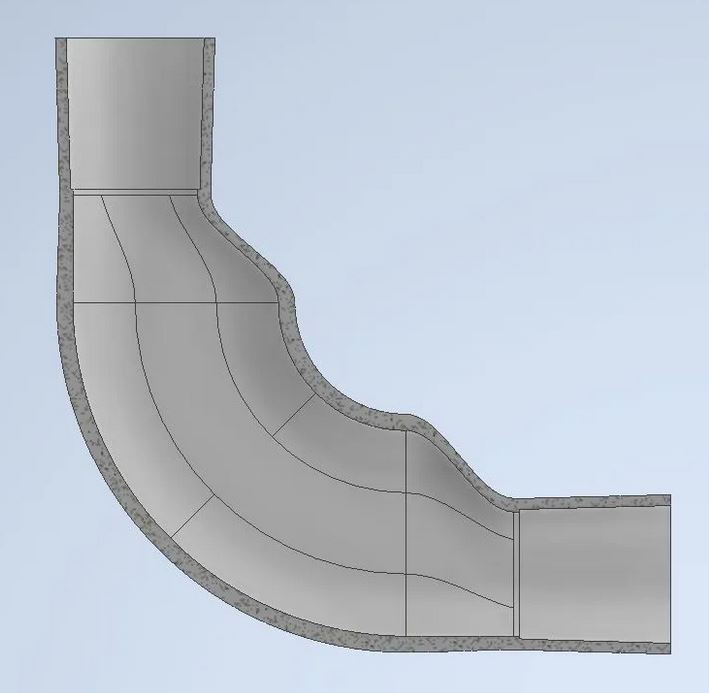

- resin vat mixing (vat tilting is good enough) to prevent resins from seperating during long prints

- decently sealed print volume: reducing the vapours/"smell"

- "speed": should be faster than the original Anycubic photon

- build volume: at least 127×80×150 mm. Larger is better (ideally upto 160x160 mm parts)

- network connectivity instead of USB-sticks or SD-card.

- budget approx. 500€.

cure and washing:

- easy to keep clean

- at least two washing containers (first stage dirty IPA, second stage "clean" IPA)

- good solution to let the resin and washing fluid drip off the print

- smooth rotation. Had to modify the Anycubic cure and wash because prints kept falling

- uniform curing. This includes curing the top and bottom of prints

- I noticed none of the printers have magnetic/spring metal build platforms. Are they outdated/no longer required?

- budget depends but for a good solution, I would spend approx. 300€.

cleaning liquid:

Is isopropanol alcohol (IPA) still the goto?

resin:

-

Will be used for structural parts meaning impact resistance paired with decent rigidity is important. In Detail impact resistance on paar with Anycubic though resin. Ideally slightly more rigid. Some wear resistance is a benefit (e.g. gears).

-

Decorative clear resin that won't yellow

-

"low cost". Would pref an under 30€/kg resin with a budget of upto 50€/kg (approx. 5kg order volume/lot size)

What am I considering at the moment?

-

used Prusa SL1S with CW1 for approx. 800€:

Last experience with Prusa firmware was outstandingly bad. The Prusa mini had constant crashes/required reboots and had even to be removed before turning the printer on as otherwise it wouldn't show firmware errors/wouldn't start.

Hardware on the other hand was pretty reliable so I hope that the SL1S is reliable, has bugfree firmware, and native prusaslicer support. Replacement parts should also be available for years to come which is great.

-

elegoo saturn 4 ultra 16K:

This printer got me thinking. Cost a fraction of the Prusa, is larger, has modern features and appears to be reliable. I remember that a while ago chitobox added DRM so I am not sure if I want to buy this if I am stuck with chitubox slicer.

-

Anycubic Photon Mono M7 pro

Instead of tilting they use a pump for resin circulation. How big of a pain is it to clean this? Anycubic slicer last time was uselss and I have no clue if Anycubic also pushed DRM meaning I couldn't just switch to a good slicer. I really like the pressure detection to detect print failures.

Cure and wash?

No idea. all the solutions I have looked at seem to be still similar to the old anycubic cure and wash. The Prusa CW1 on the other hand looks like a well-thought-out solution.

Resin?

No idea.

Those low cost Aliexpress hdmi over RJ45 are "last gen" HDMI limiting yourself to 4k@30Hz. This place already has CAT7 cabling so this would have been so much easier but sadly it isn't good enough and the current gen are to expensive.

They are fiber optic with copper for power supply and side channel. For some reason they are fairly affordable compared to OM3 fiber solutions. Probably due to them running multiple fibers allowing the transceiver to be slower and simpler. With OM4 cables there is only one fiber per direction. I think HDMI is 4 pairs so it is 5GB/s for 4 fiber compared to 20GB/s for the OM4 cable.

I personally hate copper cables. There are so many bad cables out there that it can be hard to find one that works reliably (2-5m range). Knowing now that you can buy 5m fiber optic for 30€ I probably will move forward only buying fiber optic and just coil up the excess length.