I played it too.

Rolive

I got an Orbiter 1.5 extruder and have been quite happy about it since. These days you'd be better off getting an Orbiter 2. As for the toolhead, there should be Ender 5 compatible mounts available on Printables or Thingiverse, if not you could design your own.

Creality also has its own direct drive, the Sprite Pro. That may be worth looking in to as well.

You can import a STEP model of both the Ender 5 and whatever mod you want to make to it and model your toolhead around it, that is what I did with the Mercury One project.

Duolingo is so stupidly annoying these days. It has gotten so much worse compared to a few years ago.

Constant bugging, too many popups that are almost as bad as Microsoft products. I want to learn a goddamn language not jump through a hundred hoops every single time.

Not to mention that it all boils down to a guessing game. Some questions have multiple answers and unless you choose that specific one that DuoLingo had in mind it counts as wrong. It also won't tell you why you guessed wrong.

Are there better apps these days?

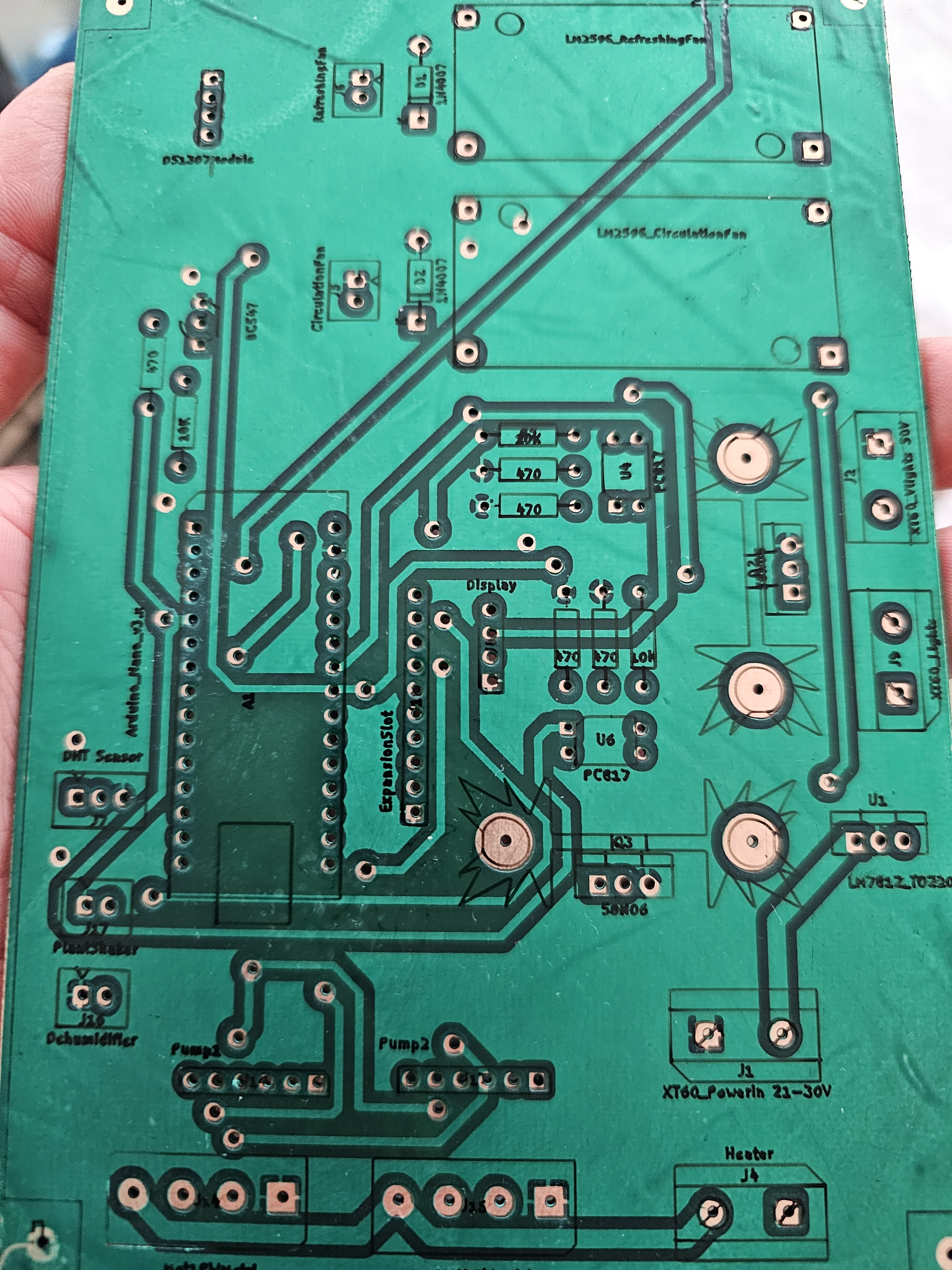

I have made something similar before for my Ender 5:

https://www.printables.com/model/1071387-ender-5-x-mgn12-detachable-toolhead-3d-print-laser

It's definitely possible and the biggest challenge is making gcode that is compatible with Marlin. I've tried using gcode substitution commands in Prusaslicer as well as programs like FlatCAM and gotten good results out of it. You could indeed just tape it to the toolhead and set your home coordinates manually.

Try reading the gcode it produces. For cutting it should only have G1 X Y Z commands but it relies on a set home position.

You can set the home position in Marlin using G92 X0 Y0 Z0 and the run the gcode from there.

I just use tweezers and a blue flame lighter. Heat it for 5 seconds then put it in the plastic. Then use the back of the tweezers as a flat surface to push it all the way in and level it.

This worked well so far and I really don't see the need for a special soldering iron bit or a press like this.